FDA, ISA 9001:2008, ISO 13485:2003 and cGMP compliant

FDA, ISA 9001:2008, ISO 13485:2003 and cGMP compliant

Our extensive range of cutting and fabricating machines provide quick turnaround with precise quality components.

With nearly 30 years’ experience serving the medical and automotive industries we can offer burr-free cut-to-length parts as small as .010" in length and .005" OD.

From Wire EDM, Sinker, Electro-chemical grinding, and CNC Swiss screw machines, MedAtlantic provides precise processes and tight tolerances on any stainless-steel component.

Electrical Discharge Machining (EDM) can be used for all electrically conductive materials.

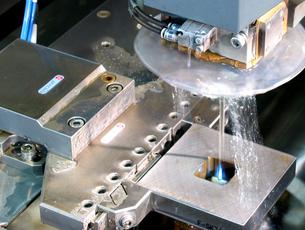

Wire EDM uses an electrically charged wire electrode which results in burr free cutting of intricate pieces with outside diameters as small as .005" It is one of the most accurate manufacturing processes available for parts with complex geometries. This results in an ability to achieve high accuracy with tight tolerances and produce precision parts with repeatability, whatever your application.

Our Sinker EDM means we can cut holes into parts without having to pre-drill a hole for the electrode making a cost-effective process for highly technical parts.

With 5-Wire EDM and 3-Sinker EDM, MedAtlantic can be your one stop shop for your prototype or full-scale production parts.

CNC Swiss Screw Machining offers a multi-axis, multi-process where sophisticated micro parts require multiple operations with close tolerances. Multi-axis ensures parts are completed in a single operation thus increasing productivity. Multi-processes include milling, drilling, and tapping resulting in increased accuracy and repeatability whilst offering reduced set-up costs.

We can hold tolerances of +/- .0001" and our experienced engineering staff mean we can reverse engineer even the most challenging of projects.

At MedAtlantic, our efficiencies and low margins have enabled our customers to return from China back to North America.

So, if you think complex parts are too cost prohibitive to be manufactured in North America, think again.

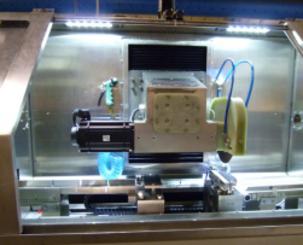

Electrochemical cutting utilizes a cutting wheel instead of a grinding wheel. Cut-to length tube components are automatically deburred during the reverse electroplating (de-plating) process.

Electrolytic fluid flushes the electrically conductive material as the wheel advances. As the distance between the wheel and the tubing diminishes the electrical current dissolves the work piece material.

Cuts are achieved without mechanical stress.

Tubing sizes as small as .016" outside diameter and burr free lengths of .300" can all be achieved with tolerances of +/- .005".

Ultrasonic precision cleaning is part of our manufacturing processes. With the need for part cleanliness an absolute imperative, whether your component is a medical or industrial application, you can rest assured your finished product is ready for your next operation or application.

Our state-of-the-art lasers including CO2 and Yag, accompanied by our experienced operators, result in high-quality, cost-effective solutions for your requirements. Computer controlled, multi-axis CNC system ensures the quality of tube cutting with outside diameters as small as .010".

We also offer high speed, accurate laser welding services of most alloys. Laser welding provides the ability to weld smaller, thinner components with a more consistent weld bead and smaller weld profile.

Laser

Marking is a process of creating surface contrast using physical effects. Laser Engraving creates surface contrast by removing a certain depth of material. All of this provides a permanent, accurate marking of your components.

At MedAtlantic, our efficiencies and low margins have enabled our customers to return from China based companies back to North America.

Whatever your requirements, MedAtlantic has the expertise, service, and quality to meet your needs.